How Monomers And Polymers Are Related

listenit

Mar 25, 2025 · 6 min read

Table of Contents

How Monomers and Polymers Are Related: A Deep Dive into Macromolecular Chemistry

The world around us is built from molecules, and many of these molecules are incredibly large. These macromolecules, or giant molecules, are fundamental to life and many industrial processes. Understanding their structure and properties is crucial to appreciating the complexity of the natural and synthetic worlds. At the heart of macromolecular chemistry lies the relationship between monomers and polymers. This article will delve deep into this relationship, exploring their definitions, the processes that connect them, and their vast applications.

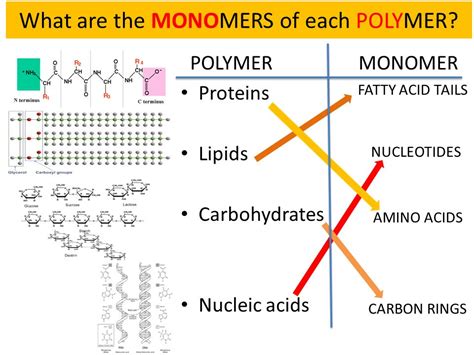

What are Monomers?

Monomers are small, relatively simple molecules that serve as the fundamental building blocks of larger molecules. Think of them as the individual LEGO bricks that can be assembled to create complex structures. They possess reactive functional groups, sites on the molecule where chemical bonds can be formed. These functional groups are essential for the polymerization process. The nature of the monomer dictates many properties of the resulting polymer.

Examples of monomers include:

- Ethylene (C₂H₄): A simple alkene that forms the basis of polyethylene (PE), a ubiquitous plastic.

- Styrene (C₈H₈): Used to produce polystyrene (PS), another common plastic used in packaging and insulation.

- Glucose (C₆H₁₂O₆): A simple sugar that serves as the monomer for cellulose and starch, essential components of plant cell walls and energy storage.

- Amino acids: These contain both an amine (-NH₂) and a carboxyl (-COOH) group and form the building blocks of proteins. Each amino acid has a different side chain (R-group), giving proteins their incredible diversity.

- Nucleotides: Composed of a sugar, a base, and a phosphate group, nucleotides are the monomers that make up DNA and RNA, the carriers of genetic information.

Types of Monomers Based on Functionality:

Monomers can be classified based on the number and type of functional groups they possess. This directly influences the way they polymerize and the structure of the resulting polymer. Some common classifications include:

- Difunctional monomers: Possessing two reactive functional groups, these monomers typically form linear polymers.

- Trifunctional monomers: With three reactive functional groups, these monomers can lead to branched or cross-linked polymers.

- Tetrafunctional monomers: These monomers, with four reactive sites, often lead to highly cross-linked, rigid networks.

What are Polymers?

Polymers are large molecules composed of repeating structural units called monomers. These units are covalently bonded together through a process called polymerization. The word "polymer" itself comes from Greek roots: "poly" meaning many and "meros" meaning part. Thus, a polymer is essentially a "many-parted" molecule.

The properties of polymers are highly dependent on:

- The type of monomer: Different monomers lead to polymers with vastly different physical and chemical properties.

- The length of the polymer chain: Longer chains generally lead to stronger and more rigid materials.

- The degree of branching or cross-linking: Branching and cross-linking affect the flexibility, strength, and melting point of the polymer.

- The arrangement of monomers within the chain (tacticity): This refers to the spatial arrangement of the monomer units along the polymer chain. Different arrangements (isotactic, syndiotactic, atactic) can lead to significant differences in polymer properties.

Types of Polymers Based on Structure:

Polymers are broadly classified based on their structure:

- Linear polymers: These consist of long, unbranched chains of monomers. Examples include polyethylene and polystyrene.

- Branched polymers: These have side chains branching off the main polymer chain. Branching reduces the density and crystallinity of the polymer.

- Cross-linked polymers: These consist of polymer chains linked together by covalent bonds, forming a three-dimensional network. This increases strength and rigidity but often reduces flexibility.

- Network polymers: These are highly cross-linked polymers with a three-dimensional structure. They are typically rigid and infusible.

The Polymerization Process: Linking Monomers to Create Polymers

The transformation of monomers into polymers occurs through a process called polymerization. This process involves the formation of covalent bonds between the reactive functional groups of the monomers. There are two primary types of polymerization:

1. Addition Polymerization (Chain-growth polymerization):

This type involves the sequential addition of monomers to a growing polymer chain. It typically requires an initiator, a molecule that starts the chain reaction. The initiator creates a reactive species that attacks a monomer, opening up a double bond (if present) and allowing another monomer to add to the chain. This continues until the chain is terminated. Examples include the polymerization of ethylene to form polyethylene and styrene to form polystyrene.

2. Condensation Polymerization (Step-growth polymerization):

This type involves the reaction between two monomers, with the elimination of a small molecule like water. The reaction proceeds stepwise, with monomers reacting to form dimers, trimers, and so on, until a high molecular weight polymer is formed. Examples include the formation of nylon (from diamines and diacids) and polyester (from diols and diacids).

Applications of Monomers and Polymers: A Vast and Diverse Landscape

The applications of monomers and polymers are incredibly widespread and span numerous industries:

1. Plastics: Polyethylene, polypropylene, polystyrene, PVC (polyvinyl chloride), and PET (polyethylene terephthalate) are just a few examples of the countless plastic materials that shape our daily lives. These plastics are used in packaging, construction, automotive parts, electronics, and countless other applications.

2. Fibers: Nylon, polyester, acrylic, and rayon are examples of synthetic fibers derived from polymerization. These materials are used in clothing, carpets, ropes, and various industrial applications.

3. Elastomers (Rubbers): Natural rubber (polyisoprene) and synthetic rubbers (e.g., styrene-butadiene rubber, neoprene) exhibit elasticity and flexibility, making them suitable for tires, seals, and other applications requiring flexibility.

4. Coatings: Polymers are used in paints, varnishes, and other coatings to protect surfaces from corrosion, wear, and weathering.

5. Adhesives: Many adhesives are based on polymers, providing strong bonds between surfaces.

6. Biomedical Applications: Biocompatible polymers are used in implants, drug delivery systems, and tissue engineering.

The Importance of Understanding the Monomer-Polymer Relationship

Understanding the relationship between monomers and polymers is crucial for:

- Designing new materials: By manipulating the type and arrangement of monomers, we can create polymers with specific properties tailored to particular applications.

- Improving existing materials: Understanding polymer structure-property relationships allows for the optimization of existing polymers for improved performance.

- Developing sustainable materials: The development of biodegradable and recyclable polymers is essential for reducing environmental impact.

- Advancing biomedical applications: The design of biocompatible and bioresorbable polymers is essential for the development of advanced medical devices and therapies.

Conclusion: A Future Shaped by Monomers and Polymers

The relationship between monomers and polymers forms the foundation of macromolecular chemistry. This field continues to evolve, driven by the need for new materials with enhanced properties and reduced environmental impact. From everyday plastics to advanced biomedical devices, monomers and polymers play an indispensable role in shaping our modern world. Further research and innovation in this field will continue to unlock new possibilities and revolutionize various industries. The incredible versatility of polymers, stemming from the simple yet powerful relationship with their monomeric building blocks, ensures their continued importance in shaping the future.

Latest Posts

Latest Posts

-

What Percent Of 12 5 Is 39

Mar 26, 2025

-

Empirical And Molecular Formula Of Ibuprofen

Mar 26, 2025

-

What Is The Molar Mass Of So2

Mar 26, 2025

-

Electrons In The Outermost Energy Level Are Called

Mar 26, 2025

-

Express The Integral As A Limit Of Riemann Sums

Mar 26, 2025

Related Post

Thank you for visiting our website which covers about How Monomers And Polymers Are Related . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.