Is Ductility A Physical Or Chemical Property

listenit

Mar 25, 2025 · 5 min read

Table of Contents

Is Ductility a Physical or Chemical Property? A Deep Dive

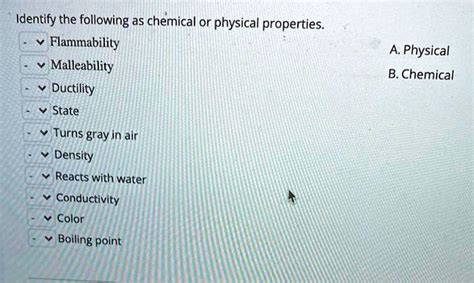

Ductility, the ability of a material to deform under tensile stress, is a fundamental property explored in materials science and engineering. Understanding whether it's a physical or chemical property is crucial for material selection and design across various applications. This article will delve into the nature of ductility, distinguishing it from chemical properties and exploring its importance in different fields. We'll also examine related concepts like malleability and tensile strength to provide a comprehensive understanding.

Defining Ductility: A Physical Property

Ductility is unequivocally a physical property. Physical properties are characteristics that can be observed or measured without changing the chemical composition of the material. Ductility falls squarely into this category. We can assess the ductility of a material by stretching or pulling it into a wire without altering its fundamental molecular structure. The process changes the material's shape, but not its chemical identity. This is in stark contrast to chemical properties, which involve changes in the substance's chemical composition.

Contrasting with Chemical Properties

Chemical properties, unlike physical properties, describe how a substance reacts or changes when interacting with other substances. Examples include flammability, reactivity with acids, and oxidation. These properties involve changes in the chemical bonds and molecular structure of the material. In contrast, measuring ductility only involves applying mechanical stress, causing deformation without any alteration of the material's chemical makeup.

Measuring Ductility

The extent of ductility is usually measured quantitatively through several methods:

-

Percent Elongation: This measures the percentage increase in length a material undergoes before fracturing under tensile stress. A higher percentage elongation signifies greater ductility.

-

Reduction in Area: This calculates the percentage decrease in the cross-sectional area of a material after being subjected to tensile stress until fracture. A greater reduction in area also reflects higher ductility.

-

Tensile Strength: While not a direct measure of ductility, tensile strength is closely related. It reflects the maximum stress a material can withstand before yielding or fracturing. High tensile strength often correlates with lower ductility, though not always. Brittle materials, for instance, may have high tensile strength but extremely low ductility.

Ductility vs. Malleability: Subtle Differences

Often confused with ductility, malleability is also a physical property describing a material's ability to deform under compressive stress. While both describe a material's ability to deform plastically, they differ in the type of stress applied. Ductility involves tensile stress (pulling), while malleability involves compressive stress (squeezing or hammering). Gold, for example, is highly ductile and malleable, allowing it to be drawn into thin wires and hammered into sheets.

Factors Affecting Ductility

Several factors significantly influence the ductility of a material:

-

Temperature: Generally, increasing temperature enhances ductility. At higher temperatures, atoms have more kinetic energy, facilitating dislocation movement and plastic deformation, making the material more easily stretched.

-

Grain Size: Fine-grained materials usually exhibit higher ductility than coarse-grained materials. The grain boundaries in fine-grained materials hinder dislocation movement, leading to a more uniform deformation.

-

Alloying Elements: Adding specific alloying elements can significantly affect ductility. Some elements can strengthen the material, thereby reducing ductility, while others can improve ductility. This is a critical consideration in materials engineering, where the precise composition is tailored to achieve desired properties.

-

Strain Rate: The speed at which a material is deformed (strain rate) affects ductility. High strain rates often reduce ductility, as the material may fracture before significant plastic deformation occurs.

-

Presence of Defects: Defects like voids, inclusions, and cracks significantly reduce ductility. These imperfections act as stress concentrators, leading to premature fracture.

Importance of Ductility in Various Applications

Ductility is a critical property with far-reaching implications across numerous industries:

1. Manufacturing and Engineering

Ductility is paramount in manufacturing processes like wire drawing, rolling, and forging. The ability to deform metals into various shapes and sizes is fundamental to producing a wide range of components, from car parts and aircraft components to everyday household items. The ductility of the material dictates the feasibility and efficiency of these manufacturing processes.

2. Construction and Infrastructure

Ductility is crucial in construction materials, particularly in applications where flexibility and resistance to impact are essential. Steel, for instance, demonstrates excellent ductility, allowing it to absorb significant energy before fracturing, making it ideal for structural applications. This property significantly contributes to the safety and longevity of buildings and bridges.

3. Electronics and Semiconductor Industry

The production of microelectronics relies heavily on ductile materials. The ability to create fine wires and intricate patterns necessitates materials with excellent ductility. Materials with high ductility allow for the creation of smaller, more efficient electronic devices.

4. Biomedical Engineering

Ductility plays a role in the design of biomedical implants. Materials used for stents, for example, need to be highly ductile to conform to the shape of blood vessels without fracturing. The ductility ensures the implant's flexibility and its ability to withstand the stresses within the body.

5. Jewelry and Decorative Arts

The malleability and ductility of precious metals like gold and silver are crucial in jewelry-making and decorative arts. These materials can be readily shaped and formed into intricate designs, showcasing the importance of ductility in artistic expression.

Ductility and Failure Mechanisms

Understanding ductility is critical in predicting material failure. Ductile materials typically exhibit significant plastic deformation before fracture, providing warning signs of impending failure. This characteristic allows for preventative measures, making them safer compared to brittle materials, which fail abruptly without much prior deformation. The ability to stretch before breaking is a key safety feature in many applications.

Conclusion: Ductility – A Defining Physical Property

In conclusion, ductility is an intrinsic physical property that is essential in characterizing a material's behavior under tensile stress. It significantly influences material selection, manufacturing processes, and structural integrity across diverse fields. Its quantitative assessment through metrics like percent elongation and reduction in area allows engineers and scientists to precisely control and optimize material performance. Understanding the factors affecting ductility and its interplay with other mechanical properties is fundamental to developing innovative and reliable materials for the future. The distinction between ductility (a physical property) and chemical properties underscores the importance of differentiating between changes in material shape and changes in chemical composition. This knowledge is crucial for designing and utilizing materials effectively and safely in countless applications.

Latest Posts

Latest Posts

-

1 2 Gal Is How Many Cups

Mar 26, 2025

-

Protons Neutrons And Electrons Of Copper

Mar 26, 2025

-

Common Factors Of 14 And 28

Mar 26, 2025

-

Why Can Ionic Compounds Conduct Electricity

Mar 26, 2025

-

Whats The Diameter Of A Tennis Ball

Mar 26, 2025

Related Post

Thank you for visiting our website which covers about Is Ductility A Physical Or Chemical Property . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.