Is Distance Decreases On A Pulley

listenit

Mar 27, 2025 · 6 min read

Table of Contents

Does Distance Decrease on a Pulley System? A Deep Dive into Mechanical Advantage

The humble pulley, a simple machine consisting of a wheel with a grooved rim around which a rope, cable, or belt passes, is often underestimated. While seemingly straightforward, the mechanics behind a pulley system, particularly its effect on distance, can be surprisingly complex and counter-intuitive. This article will delve deep into the relationship between distance and pulley systems, exploring different configurations and addressing common misconceptions. We will examine how the number of pulleys, their arrangement, and the presence of friction influence the distance traveled by the input force compared to the distance moved by the load.

Understanding Mechanical Advantage

Before we explore the impact on distance, we must first understand the concept of mechanical advantage (MA). Mechanical advantage quantifies the amplification of force achieved by using a simple machine like a pulley. It's the ratio of the output force (the force exerted on the load) to the input force (the force applied to the rope or cable). A higher mechanical advantage means you can lift a heavier load with less effort.

MA = Output Force / Input Force

However, this increased force comes at a cost: increased distance. This fundamental principle of physics, the conservation of energy, dictates that the work done on the system remains constant (ignoring friction). Work is defined as force multiplied by distance:

Work = Force x Distance

Since work remains constant, an increase in force (higher MA) necessitates a corresponding increase in the distance the input force must travel. In simpler terms, you gain force at the expense of distance.

Pulley Systems: Configurations and Distance

The relationship between distance and pulley systems is heavily dependent on the configuration of the pulleys. Let's analyze some common setups:

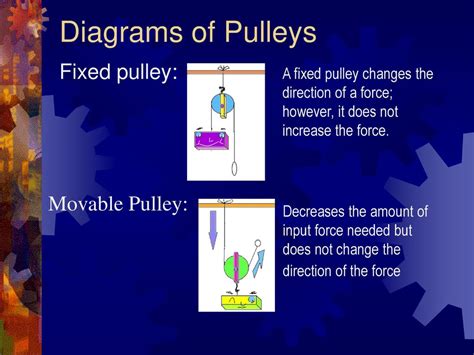

1. Single Fixed Pulley

A single fixed pulley changes the direction of the force but does not provide any mechanical advantage. If you pull the rope 1 meter, the load will also move 1 meter. The MA in this case is 1. This is because the input force and the output force are equal in magnitude.

Distance Relationship: 1:1 (Input distance = Output distance)

2. Single Movable Pulley

A single movable pulley, on the other hand, does provide a mechanical advantage. The load is attached to the pulley itself, and the rope passes around it. In this configuration, you only need to pull with half the weight of the load to lift it. However, to raise the load 1 meter, you must pull the rope 2 meters.

Distance Relationship: 2:1 (Input distance = 2 x Output distance)

MA = 2

This illustrates the trade-off: you gain a mechanical advantage of 2 (lifting twice the weight with the same force), but you have to pull twice the distance.

3. Multiple Pulley Systems

The complexity and the distance relationship increase dramatically with multiple pulleys. We can create more complex systems using combinations of fixed and movable pulleys. These systems can provide significantly higher mechanical advantages.

Consider a system with two fixed pulleys and two movable pulleys. The mechanical advantage of such a system can be as high as 4, meaning you lift four times the weight with the same force. However, to raise the load 1 meter, you'll need to pull the rope 4 meters.

The general rule is that the mechanical advantage of a pulley system is approximately equal to the number of supporting ropes lifting the load. It's crucial to remember that this is an approximation, and the presence of friction and the weight of the pulleys themselves will slightly alter the actual mechanical advantage and the distance relationship.

Distance Relationship (General Rule): MA : 1 (Input distance = MA x Output distance)

4. The Impact of Friction

The analysis above assumes an ideal system with no friction. In reality, friction between the rope and the pulleys, as well as within the pulley bearings, will reduce the mechanical advantage and alter the distance relationship. Some energy is lost to overcome friction, meaning you'll need to exert more force and pull a slightly greater distance than predicted by the ideal model. The more pulleys in the system, the greater the cumulative effect of friction.

5. Efficiency in Pulley Systems

The efficiency of a pulley system is a measure of how much of the input work is converted into useful work in lifting the load. Friction reduces efficiency. A perfectly efficient pulley system would have an efficiency of 100%, but real-world systems always have lower efficiencies.

Efficiency = (Output Work / Input Work) x 100%

Efficiency depends on factors such as the material of the pulleys and ropes, lubrication, and the design of the system.

Common Misconceptions

Several misconceptions surround the distance-pulley relationship:

-

Misconception 1: Pulley systems magically reduce distance. They don't. They trade off distance for force. You gain a mechanical advantage (increased force), but you always have to pull a proportionally greater distance.

-

Misconception 2: The distance always relates directly to the number of pulleys. While the number of supporting ropes often approximates the mechanical advantage, it's not a strict rule for all pulley configurations. The arrangement of the pulleys is crucial.

-

Misconception 3: Ignoring Friction is always acceptable. In simple calculations, ignoring friction can provide a useful approximation. However, for precise analysis, especially in complex systems or high-load applications, friction must be considered.

Advanced Topics and Applications

The principles discussed above form the basis for understanding more advanced pulley systems and their applications. Here are some examples:

-

Block and Tackle Systems: These systems employ multiple pulleys arranged in specific configurations to achieve very high mechanical advantages. They are commonly used in heavy lifting operations such as construction and marine applications.

-

Differential Pulleys: These use two pulleys of different diameters to achieve a higher mechanical advantage than a simple multiple pulley system.

-

Pulley Systems in Robotics and Automation: Pulley systems are integral parts of many robotic mechanisms, enabling precise and controlled movement of robotic arms and other components.

-

Belt Drives: Pulley systems, in the form of belt drives, are used to transmit power in many mechanical systems, from bicycles to industrial machinery. The ratio of pulley diameters determines the speed and torque ratios.

Conclusion

The relationship between distance and a pulley system is not a simple one. It's directly tied to the system's mechanical advantage and the fundamental principle of conservation of energy. While pulley systems can significantly reduce the effort required to lift heavy objects, this reduction in effort always comes at the cost of increased distance. Understanding the configurations, the impact of friction, and the trade-off between force and distance is essential for anyone working with or designing pulley-based systems. From simple tasks to complex engineering challenges, the principles discussed here offer a comprehensive understanding of how these ubiquitous machines function.

Latest Posts

Latest Posts

-

Groups 3 12 On The Periodic Table

Mar 30, 2025

-

Lewis Structure Of N Ch3 3

Mar 30, 2025

-

What Is The Name For The Compound N2o5

Mar 30, 2025

-

Is Radius The Same As Diameter

Mar 30, 2025

-

What Is 35 In A Fraction

Mar 30, 2025

Related Post

Thank you for visiting our website which covers about Is Distance Decreases On A Pulley . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.