Is Malleable A Metal Or Nonmetal

listenit

Mar 14, 2025 · 5 min read

Table of Contents

Is Malleable a Metal or Nonmetal? Understanding Material Properties

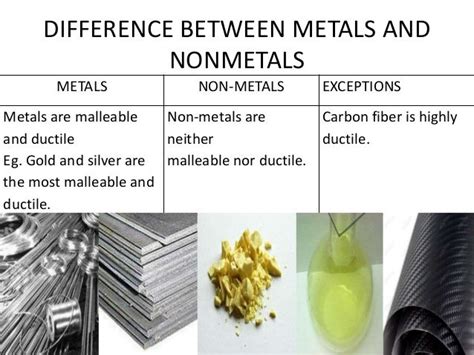

The term "malleable" describes a material's ability to be deformed under compressive stress; that is, to be hammered or pressed into shape without breaking. While often associated with metals, malleability isn't exclusive to them. Understanding what makes a material malleable requires delving into its atomic structure and bonding characteristics. This article will explore the relationship between malleability, metals, and nonmetals, examining the exceptions and nuances that challenge a simple binary classification.

The Defining Characteristics of Metals

Metals, as a class of materials, are renowned for their malleability, ductility (ability to be drawn into wires), and conductivity (of heat and electricity). These properties are directly linked to their atomic structure and bonding:

Metallic Bonding: The Key to Malleability

Metals are characterized by metallic bonding, where valence electrons are delocalized and shared among a "sea" of electrons surrounding positively charged metal ions. This "sea" of electrons acts as a glue, holding the metal ions together. Crucially, this bonding is non-directional, meaning the attractive forces between ions are relatively uniform in all directions.

This non-directional bonding is the key to a metal's malleability. When a force is applied, the metal ions can slide past each other without disrupting the overall structure. The delocalized electrons readily adapt to the new arrangement, maintaining the metallic bond and preventing the material from fracturing.

Other Factors Influencing Malleability in Metals

While metallic bonding is fundamental, other factors influence a metal's malleability:

- Temperature: Higher temperatures generally increase malleability as the increased kinetic energy allows for easier movement of ions.

- Purity: Impurities in a metal can disrupt the uniform arrangement of ions, hindering the sliding process and reducing malleability. Alloying, the process of adding other elements, can sometimes increase malleability, but often affects it depending on the alloying elements.

- Crystal Structure: The arrangement of atoms in a metal's crystal lattice influences its malleability. Face-centered cubic (FCC) structures, like those found in copper and aluminum, tend to be more malleable than body-centered cubic (BCC) structures, like those found in iron. This is due to the different slip systems (planes along which atoms can slide) available in each structure.

- Grain Size: Smaller grains generally improve malleability as they present more grain boundaries, allowing for easier deformation. Larger grains can lead to more localized stress and potential cracking.

Nonmetals and Malleability: The Exceptions

While metals are typically associated with high malleability, some nonmetals exhibit the property to a lesser degree, albeit with significantly different mechanisms. The malleability in nonmetals is not as pronounced as in metals due to their different bonding characteristics:

Covalent Bonding in Nonmetals

Nonmetals are primarily characterized by covalent bonding, where atoms share electrons to achieve a stable electron configuration. Unlike metallic bonding, covalent bonding is highly directional, meaning the bonds are strong in specific directions. This directional nature makes it difficult for atoms to slide past each other without breaking the bonds, resulting in brittleness rather than malleability.

Examples of Nonmetals Exhibiting Limited Malleability:

- Graphite: A form of carbon, graphite is an exception. Its structure consists of layers of carbon atoms held together by strong covalent bonds within each layer but weaker van der Waals forces between layers. This layered structure allows for some degree of malleability as layers can slide over each other, making it suitable for use in pencils. However, this malleability is far less pronounced than that of metals.

- Sulfur: Sulfur, in its crystalline form, exhibits some limited malleability at room temperature. It can be ground into powder but cannot be shaped extensively like metals. However, increased temperature makes it more malleable.

These examples highlight that while the strong directional nature of covalent bonds usually precludes significant malleability, specific structural arrangements can provide a degree of it. The mechanism is fundamentally different from metallic malleability.

Malleability and the Intermediate Cases: Metalloids and Alloys

The distinction between malleable metals and non-malleable nonmetals is not always clear-cut. Some materials fall into intermediate categories:

Metalloids: A Blend of Properties

Metalloids (or semimetals) possess properties intermediate between metals and nonmetals. Their malleability can vary greatly depending on the specific metalloid and its crystalline structure. Some exhibit a degree of malleability, while others are brittle. Silicon, for example, is brittle at room temperature but becomes more malleable at higher temperatures.

Alloys: Tuning Malleability

Alloys are mixtures of metals, and sometimes non-metals, designed to achieve specific properties. Alloying can significantly alter the malleability of a metal. For instance, adding carbon to iron produces steel, which exhibits a wide range of malleability depending on the carbon content. Low-carbon steel is very malleable, while high-carbon steel is much less so. Other alloying elements can also dramatically impact malleability.

Conclusion: Beyond a Simple Binary Classification

Malleability is a crucial material property, but its relationship with metals and nonmetals is not strictly binary. While metallic bonding, with its non-directional nature, facilitates the exceptional malleability observed in most metals, some nonmetals display limited malleability due to specific structural arrangements or conditions. Furthermore, metalloids and alloys demonstrate the complexity of this property, showcasing how material composition and structure can finely tune malleability. Understanding these nuances is essential for material scientists and engineers selecting materials for specific applications where formability is critical. The discussion above should serve as a comprehensive overview of the multifaceted relationship between malleability and material classification, moving beyond the simplistic metal/nonmetal dichotomy. Further research into specific material properties will enhance one's understanding of this complex phenomenon.

Latest Posts

Latest Posts

-

How Many Moles Of Ions Are In Of

Mar 14, 2025

-

What Is The Difference Between A Coefficient And A Subscript

Mar 14, 2025

-

What Is The Least Common Factor Of 9 And 15

Mar 14, 2025

-

What Is The Correct Equation For Cellular Respiration

Mar 14, 2025

-

How Many Pounds Is 1 2 Kg

Mar 14, 2025

Related Post

Thank you for visiting our website which covers about Is Malleable A Metal Or Nonmetal . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.