Diameter Of A Can Of Coke

listenit

Mar 21, 2025 · 5 min read

Table of Contents

Decoding the Diameter of a Can of Coke: A Deep Dive into Dimensions and Design

The humble can of Coca-Cola. A ubiquitous symbol of refreshment, a cultural icon, and a surprisingly complex piece of engineering. While seemingly simple, the precise dimensions of a Coke can, specifically its diameter, are the result of meticulous design considerations balancing functionality, manufacturing efficiency, and marketing appeal. This article delves deep into the fascinating world of the Coca-Cola can's diameter, exploring its history, variations, and the intricate reasons behind its seemingly insignificant measurements.

The Standard Diameter: A Myth and Reality

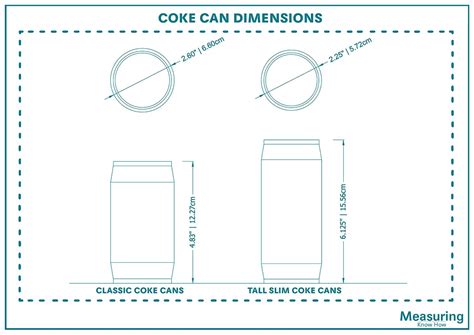

Many assume there's one definitive diameter for a can of Coke. This isn't entirely accurate. While a standard size exists, variations exist due to factors like can type (regular, diet, zero sugar), regional differences in manufacturing, and even slight variations over time. The generally accepted diameter for a standard 12-ounce (355ml) can of Coca-Cola is approximately 2.6 inches (66mm). However, measuring several cans might reveal minor discrepancies. This seemingly insignificant variation highlights the complexities inherent in large-scale manufacturing and distribution.

Factors Influencing Diameter Variations:

-

Manufacturing Tolerances: Even with precise machinery, minor variations in can dimensions are unavoidable during the manufacturing process. These variations are usually within acceptable tolerances and do not impact the functionality or consumer experience.

-

Can Material: The type and thickness of aluminum used in manufacturing slightly influence the final diameter. These differences are usually negligible, but they contribute to the overall variations observed.

-

Regional Differences: Coca-Cola operates globally, and slight variations in manufacturing processes across different regions can lead to minor differences in can dimensions. These variations are typically minimal and mostly imperceptible to the average consumer.

-

Product Variations: Diet Coke, Coke Zero, and other variations might have slightly different can diameters, although the differences are often subtle. This could be due to minor formulation differences or adjustments in the manufacturing process.

Beyond the Diameter: The Importance of Can Design

The diameter of a Coca-Cola can isn't an arbitrary measurement. It's a crucial aspect of its overall design, carefully considered to optimize several key factors:

1. Ergonomics and Grip:

The can's diameter is designed for comfortable handling. Too small, and the can might feel awkward and difficult to grip. Too large, and it could be cumbersome to hold, especially for those with smaller hands. The 2.6-inch diameter achieves a balance, allowing for a secure and comfortable grip. This is crucial for consumer experience and makes the can more user-friendly.

2. Stackability and Transportation:

The diameter, combined with the can's height, is essential for efficient stacking and transportation. The cylindrical shape allows for optimal space utilization during shipping and storage, minimizing wasted space and reducing transportation costs. Efficient stacking directly affects the overall supply chain.

3. Manufacturing Efficiency:

The chosen diameter is compatible with existing high-speed manufacturing equipment. This streamlined process allows for mass production at an economical scale, ensuring the affordability of the product. The efficient manufacturing process also minimizes environmental impact by reducing waste and energy consumption.

4. Marketing and Branding:

While seemingly insignificant, the can's dimensions are also part of the overall branding. The familiar shape and size are instantly recognizable, contributing to the iconic status of the product. The consistent design reinforces brand identity and ensures brand recognition.

The Historical Evolution of the Can: A Journey Through Dimensions

The Coca-Cola can hasn't always been the same size. Early cans differed in dimensions, reflecting changes in technology, materials, and consumer preferences. Studying the evolution of the can provides valuable insights into the factors shaping its design.

From Glass Bottles to Aluminum Cans:

Initially, Coca-Cola was primarily sold in glass bottles. The transition to aluminum cans was a significant shift, influenced by factors like durability, lightweight portability, and cost-effectiveness. The aluminum can design had to optimize for both functionality and aesthetics.

Innovations in Can Technology:

Over time, can technology has advanced significantly. Innovations in aluminum production, sealing techniques, and printing methods have impacted the can's dimensions and design. The improved manufacturing processes have allowed for greater precision and consistency in production, even with the complex shapes and designs of modern cans.

The Scientific Precision Behind the Seemingly Simple Can

The seemingly simple cylindrical shape of the Coca-Cola can belies the sophisticated engineering and scientific principles behind its design. Every aspect, from the material thickness to the diameter, is calculated to optimize various factors like structural integrity, resistance to damage, and manufacturing costs. Analyzing the can from an engineering perspective highlights the expertise needed to produce millions of these seemingly simple products daily.

Material Science and Structural Integrity:

The thickness of the aluminum used in the can is determined by balancing strength and weight. A thicker can would be more durable but heavier and more expensive to produce. A thinner can would be lighter and cheaper but more susceptible to damage. The balance between these factors is a crucial part of the engineering process.

Finite Element Analysis (FEA):

Computer-aided engineering (CAE) and Finite Element Analysis (FEA) are likely employed during the design and optimization of the can. These techniques allow engineers to simulate real-world conditions, such as stacking and transportation stress, helping determine the optimal material thickness and dimensions to ensure the can's structural integrity.

Conclusion: More Than Just a Diameter

The diameter of a can of Coca-Cola is much more than just a simple measurement. It represents the culmination of design, engineering, manufacturing expertise, and marketing strategy. From optimizing ergonomics and enhancing transportation efficiency to maintaining brand recognition and ensuring cost-effectiveness, every detail has been carefully considered. The seemingly insignificant 2.6-inch diameter encapsulates decades of innovation and precision, highlighting the complexity hidden within an everyday object. Understanding the intricate design considerations behind a seemingly simple item like a Coca-Cola can reveals the power of careful planning and its impact on global consumer culture. The consistent size and shape, coupled with global recognition, showcases the power of successful product design and branding. The can itself is a testament to human ingenuity and the remarkable influence it has on daily life.

Latest Posts

Latest Posts

-

What Is The Most Reactive Element

Mar 21, 2025

-

What Is The Electron Configuration For Ne

Mar 21, 2025

-

Dna Replication Is Considered Semiconservative Because

Mar 21, 2025

-

Find Two Positive Real Numbers Whose Product Is A Maximum

Mar 21, 2025

-

How Many Inches In A 1 4 Yard

Mar 21, 2025

Related Post

Thank you for visiting our website which covers about Diameter Of A Can Of Coke . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.