A Drum Rotates Around Its Central

listenit

Apr 08, 2025 · 6 min read

Table of Contents

A Drum Rotates Around Its Central Axis: Exploring the Physics and Engineering Marvels

The seemingly simple act of a drum rotating around its central axis belies a rich tapestry of physics principles and engineering marvels. From the humble child's toy to massive industrial rollers, the rotational motion of a cylindrical object offers a fascinating case study in mechanics, impacting fields ranging from manufacturing and transportation to music and entertainment. This article delves deep into the science behind this fundamental movement, examining its underlying principles and exploring its diverse applications.

Understanding Rotational Motion: Beyond Linearity

Unlike linear motion, where objects move in a straight line, rotational motion involves movement around a fixed axis. In the case of a drum rotating around its central axis, every point on the drum's surface traces a circular path, all with the same angular velocity. This shared angular velocity is key to understanding the drum's behavior. It's measured in radians per second (rad/s) or revolutions per minute (rpm), providing a consistent metric for the rate of rotation regardless of the drum's radius.

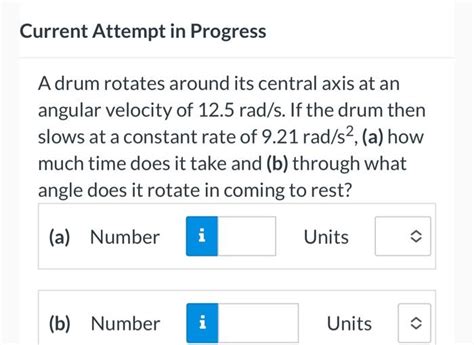

Angular Velocity and Angular Acceleration

The concept of angular velocity (ω) describes how quickly the drum rotates. A higher angular velocity means a faster rotation. Angular acceleration (α), on the other hand, indicates how quickly the angular velocity changes. A positive angular acceleration implies an increase in rotational speed, while a negative acceleration (deceleration) means the drum is slowing down. These quantities are analogous to linear velocity and acceleration, but they describe rotational movement rather than linear movement.

Torque: The Rotational Force

To initiate or alter the rotation of a drum, a force is needed. However, this force isn't simply a linear push or pull; it's a torque (τ). Torque is the rotational equivalent of force and depends on both the magnitude of the applied force and the distance from the axis of rotation where the force is applied. The further the force is applied from the center, the greater the torque and the easier it is to accelerate the drum's rotation. This principle is why a long wrench is easier to use than a short one to loosen a bolt.

Moment of Inertia: Resistance to Rotational Change

Just as mass resists changes in linear motion (inertia), objects resist changes in rotational motion. This resistance is quantified by the moment of inertia (I). For a cylindrical drum, the moment of inertia depends on its mass and the distribution of that mass around its axis. A drum with more mass concentrated further from the center will have a higher moment of inertia and will be harder to accelerate or decelerate.

Relationship Between Torque, Moment of Inertia, and Angular Acceleration

The fundamental equation governing rotational motion elegantly links these three concepts:

τ = Iα

This equation states that the net torque acting on a drum is directly proportional to its angular acceleration and its moment of inertia. A larger torque leads to a greater angular acceleration, while a larger moment of inertia resists angular acceleration.

Applications of Rotating Drums: A Diverse Spectrum

The rotation of drums finds applications across a vast range of industries and scenarios:

Industrial Processes: From Manufacturing to Mining

Rotating drums are ubiquitous in industrial settings. They are used extensively in:

- Material Handling and Processing: Rotating drums are integral to various processes, including mixing, drying, and conveying materials. Examples include cement kilns (rotating cylinders for cement production), dryers for various materials, and rock tumblers for polishing stones.

- Mining and Mineral Processing: Large rotating drums are utilized for crushing, grinding, and separating minerals. Their ability to handle bulk materials efficiently makes them a cornerstone of modern mining operations.

- Waste Management: Rotating drums play a role in waste processing, such as incineration or composting, facilitating efficient material handling and processing.

Transportation and Logistics: The Rotating Heart of Conveyors

Rotating drums are crucial components of various conveyor systems, playing a key role in:

- Belt Conveyors: Rotating drums act as driving mechanisms or idlers, ensuring smooth and efficient movement of materials along conveyor belts.

- Roller Conveyors: A series of rotating cylindrical rollers facilitate the movement of goods, commonly seen in warehouses and distribution centers.

Music and Entertainment: The Rhythmic Beat

The humble drum, a percussion instrument, relies entirely on the rotation of its cylindrical body, producing captivating rhythms that resonate across cultures and genres:

- Drums Across Cultures: Drums have been fundamental to musical traditions worldwide, from the complex rhythms of West African djembe to the driving beat of rock and roll.

- Specialized Drums: Different types of drums are designed with varying sizes, materials, and construction, impacting their sound and playability.

Other Applications: Expanding the Horizons

The rotation of drums extends to a surprising number of applications:

- Printing: Rotating drums are employed in printing presses, allowing for continuous printing onto rolls of paper or other materials.

- Textiles: Rotating drums are used in textile manufacturing for dyeing, washing, and other processing steps.

- Food Processing: Rotating drums are used in the food industry for mixing, coating, and other processing applications.

Engineering Challenges and Solutions: Optimizing Rotational Efficiency

Designing and manufacturing rotating drums efficiently and effectively necessitates addressing several key engineering challenges:

Bearing Selection and Lubrication: Minimizing Friction and Wear

The bearings supporting a rotating drum are critical components. Appropriate bearing selection minimizes friction and wear, ensuring smooth rotation and extending the drum's lifespan. Effective lubrication is also essential, reducing friction and preventing premature bearing failure.

Material Selection: Balancing Strength, Durability, and Cost

The material of the drum must balance strength, durability, corrosion resistance, and cost. Steel is frequently used for its strength and durability, while other materials like polymers may be suitable for specific applications requiring lighter weight or resistance to certain chemicals.

Balancing: Preventing Vibration and Instability

An unbalanced drum will vibrate during rotation, causing noise, wear, and potential damage. Precise balancing techniques are essential to ensure smooth and stable rotation.

Safety Considerations: Protecting Workers and Equipment

Rotating drums can pose safety risks if not properly designed and operated. Safety features like guards, interlocks, and emergency stops are essential to prevent accidents.

Conclusion: A Foundation of Modern Technology

The seemingly simple motion of a drum rotating around its central axis underpins a vast array of technologies and processes. Understanding the underlying physics principles, along with addressing the associated engineering challenges, is essential for designing efficient and effective rotating drum systems. From the industrial scale to everyday applications, the rotating drum continues to be a vital component of our modern world, showcasing the powerful interplay of physics and engineering ingenuity. Further exploration into specific applications and their unique design considerations will undoubtedly reveal even deeper intricacies within this fascinating field. The continuous advancements in materials science, bearing technology, and computational modeling further expand the potential applications and efficiency of rotating drums, promising an even more significant role in future technologies.

Latest Posts

Latest Posts

-

Number Of Valence Electrons For Boron

Apr 08, 2025

-

What Holds Two Strands Of Dna Together

Apr 08, 2025

-

What Happens To Atoms After A Chemical Change

Apr 08, 2025

-

What Decimal Is Equivalent To 1 3

Apr 08, 2025

-

Vertical Angles Are Supplements Of Each Other

Apr 08, 2025

Related Post

Thank you for visiting our website which covers about A Drum Rotates Around Its Central . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.