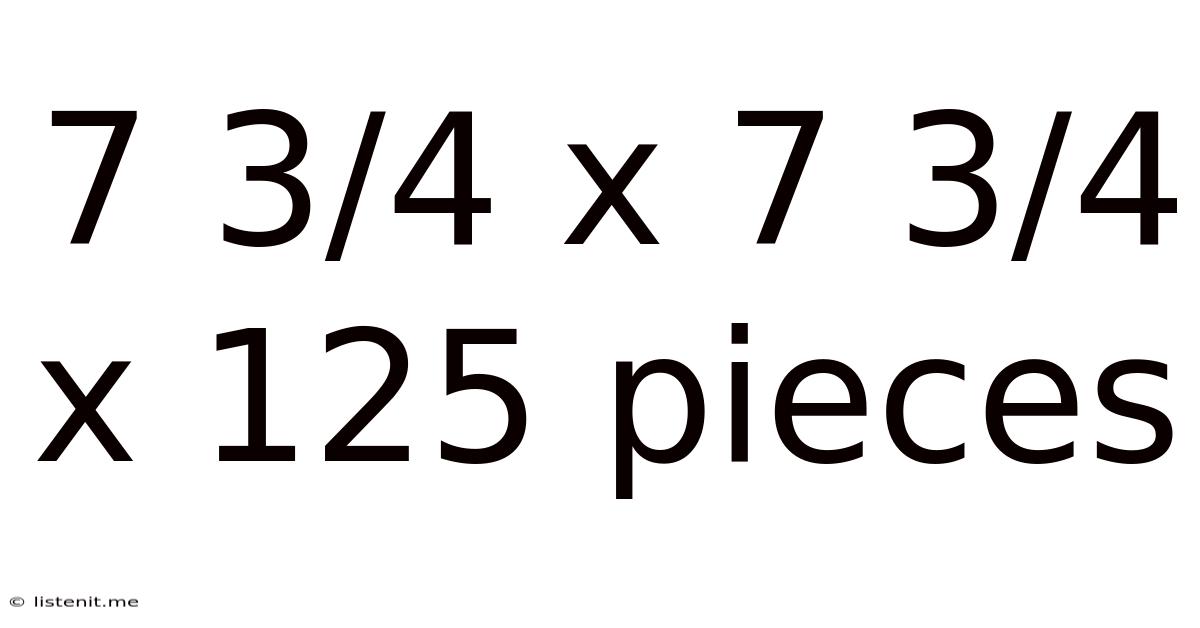

7 3/4 X 7 3/4 X 125 Pieces

listenit

May 18, 2025 · 5 min read

Table of Contents

Decoding the Mystery: 7 3/4 x 7 3/4 x 125 Pieces – A Deep Dive into Dimensions, Applications, and Potential Uses

The seemingly simple dimensions "7 3/4 x 7 3/4 x 125 pieces" can actually represent a wide array of possibilities depending on the context. This article aims to unravel the mystery behind these measurements, exploring their potential applications across various industries and delving into the importance of understanding precise specifications in manufacturing and design.

Understanding the Dimensions: A Breakdown

The dimensions 7 3/4 x 7 3/4 represent a square or near-square shape, measuring 7.75 inches on each side. The "125 pieces" indicates a quantity – 125 units with these dimensions. This seemingly simple information opens up a world of possibilities, and the specific application heavily depends on the material and intended use.

Potential Materials

The material used dramatically alters the possible applications. Let's consider a few:

-

Wood: This could represent 125 wooden blocks, tiles, or components for furniture making, model building, or even crafting. The size suggests they could be used for smaller projects or as individual parts within larger structures. Think of intricate wooden puzzles, building blocks for children, or components for bespoke furniture.

-

Metal: If the material is metal, such as aluminum or steel, these could be components for various industrial applications. They might be plates, shims, or parts for machinery. Precise dimensions are critical in engineering, making these accurate specifications crucial. The material's properties – strength, weight, conductivity – will influence its function.

-

Plastic: This could be anything from toy components to parts for electronic devices. Plastic's versatility allows for a range of uses, from containers and packaging to specialized components in mechanical assemblies. The plastic's type – ABS, polycarbonate, etc. – further determines its suitability.

-

Ceramic or Glass: These dimensions could be tiles, components for mosaics, or specialized parts for laboratories or industrial processes requiring heat resistance or chemical inertness. The material's properties dictate its ideal use.

-

Other Materials: The possibility also extends to composite materials, concrete (especially in smaller, specialized applications), or even specialized polymers with unique characteristics.

Applications Across Industries

The versatility of these dimensions leads to applications across diverse industries:

1. Manufacturing and Industrial Applications

-

Machinery Components: Metal or plastic pieces of this size could serve as crucial parts in various machines, requiring precision manufacturing and strict adherence to dimensional accuracy.

-

Automotive: Smaller parts in vehicles, from interior components to elements within the engine compartment, could utilize these dimensions.

-

Electronics: Precisely cut components in electronics manufacturing, like circuit board supports or housing parts for smaller devices.

2. Construction and Building Materials

-

Decorative Tiles: Ceramic or stone tiles of these dimensions would be suitable for various decorative applications, in wall cladding or flooring.

-

Specialized Construction Components: In niche construction projects, these could be components in custom-built structures.

3. Crafts and Hobbies

-

Woodworking: As previously mentioned, these could be the foundation for countless craft projects, including small boxes, furniture components, and intricate wood carvings.

-

Model Building: They could serve as building blocks for models, architectural models, or even custom-designed miniatures.

-

Jewelry Making: If the material is suitable, these pieces could even serve as components in larger jewelry pieces.

4. Packaging and Shipping

- Custom Packaging: These dimensions could be the size of custom containers for smaller products, designed for efficient shipping and storage.

5. Education and Research

-

Educational Tools: Wooden blocks of this size could be effective tools in teaching spatial reasoning, geometry, and other mathematical concepts.

-

Laboratory Equipment: Depending on the material, these could form parts of lab equipment, especially if high precision is required.

The Importance of Precision

Regardless of the intended application, the accuracy of the 7 3/4 x 7 3/4 dimensions is critical. Even slight deviations can compromise the functionality and integrity of the final product. In manufacturing, tolerances are often specified to ensure that the parts meet the required standards. These tolerances might be in fractions of a millimeter, highlighting the importance of precision machining techniques.

Tolerances and Manufacturing Processes

Different manufacturing processes have different tolerances. For instance, CNC machining (Computer Numerical Control) generally offers higher precision compared to casting or molding. Understanding the tolerances required depends on the specific application and the material properties. A slight deviation in a wooden block for craft might not matter significantly, but a similar deviation in a metal component for aerospace engineering could have catastrophic consequences.

Quality Control and Inspection

Rigorous quality control procedures are essential to ensure that all 125 pieces meet the specified dimensions. Inspection methods can include visual inspection, dimensional measurement with calipers or micrometers, and even more advanced techniques like coordinate measuring machines (CMMs) for extremely high precision.

The Role of Materials Selection

Selecting the right material is just as critical as ensuring precise dimensions. The material's properties – strength, durability, weight, thermal conductivity, resistance to chemicals, etc. – must align with the specific application. The selection will directly impact the final product's functionality, performance, and cost.

Material Properties and Application Suitability

For example, a metal part needs to withstand stress and strain, while a plastic part might prioritize flexibility and lower weight. Ceramic might be chosen for its heat resistance, while wood could be selected for its aesthetic qualities or ease of crafting. The choice should be carefully considered based on the desired performance characteristics and the overall cost-effectiveness.

Conclusion: Unlocking the Potential

The seemingly simple specification of "7 3/4 x 7 3/4 x 125 pieces" unlocks a world of possibilities. Understanding the implications of these dimensions – the potential materials, manufacturing processes, and applications – is crucial for anyone involved in design, manufacturing, or any field that requires precisely specified components. The critical role of precision, material selection, and quality control ensures the successful implementation of these seemingly small but significantly impactful units in a wide range of industries. This detailed analysis hopefully sheds light on the broader context and potential uses hidden within this seemingly simple specification. Further research into the specific material and intended application will reveal even more possibilities.

Latest Posts

Latest Posts

-

Organisms That Live In The Hadal Zone

Jun 05, 2025

-

How Does The Immune System Work With The Skeletal System

Jun 05, 2025

-

The Present And Future Of Bispecific Antibodies For Cancer Therapy

Jun 05, 2025

-

What Do Broviac And Hickman Catheters Do

Jun 05, 2025

-

Shock Wave Therapy For Achilles Tendinopathy

Jun 05, 2025

Related Post

Thank you for visiting our website which covers about 7 3/4 X 7 3/4 X 125 Pieces . We hope the information provided has been useful to you. Feel free to contact us if you have any questions or need further assistance. See you next time and don't miss to bookmark.